Drop into neutral at 80,000 lbs and the shoulder better be empty. That’s what the DT12 does when the split pin sticks, the air tank dips, or the clutch won’t release. One blink, and you’re coasting with “NO GEAR” flashing across the dash.

The Detroit DT12 was built to squeeze fuel, not to forgive abuse. It’s lean, fast, and deeply wired into the engine. But that same tight control turns brittle when air gets wet, sensors glitch, or calibration goes wrong. Mechanical failures don’t always show up as broken parts; they show up as bad data.

This guide cuts through the noise. You’ll see how the DT12 works, what fails most, which codes point to real trouble, and how to keep it moving past 1.2 million without chasing ghosts through the CAN bus.

1. Why DT12 failures don’t look like old-school gearbox problems

DT12 shifts like a manual but dies like a sensor

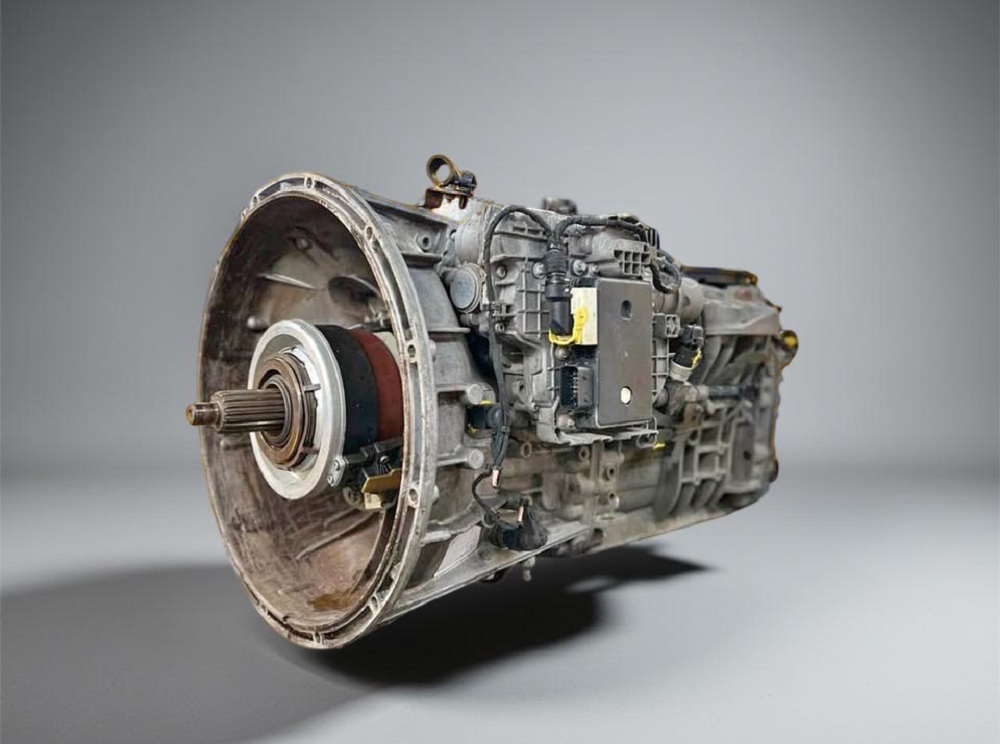

The DT12 runs a true geartrain, clutch, mainshaft, countershaft, no torque converter. But it shifts by wire. You’ve got a pneumatic clutch actuator, aluminum case, and super-finished gears that demand exact tolerances. The result is slick, light, and unforgiving.

The single-countershaft layout sheds weight, but it’s not built to soak abuse like a 13-speed. Every shift relies on millisecond timing, stable voltage, and bone-dry air. Lose any of that, and you’re stuck in neutral with no busted teeth to blame.

Skip mechanical blame too fast, though, and you miss the real problem. Wear still happens. It just hides behind flaky sensors, aborted learns, or split pins that jam in their bore when cold.

One bad signal can freeze the whole system

The CPC, TCM, and MCM share everything, engine torque, clutch command, shift sequence. They ride the same CAN network and expect clean, continuous signals. A corroded pin, wet SAM cab module, or flaky ground throws the whole triangle off balance.

The TCM doesn’t get to guess. If torque cut data shows a delay or drop, the shift aborts. If the CPC sees voltage bounce on a range sensor, it flags a mismatch and dumps the clutch. The logic favors protection, not progress.

Drivers see this as a failed box. But the clutch may be fine. The gears may be ready. The issue lives in the wiring or air, and that’s why shotgun swaps never stick. Find the broken signal or the moisture that scrambled it, or it comes back at the next cold start.

Different DT12s fail in different ways

| Series | Model | Max torque (lb-ft) | GCW limit (lbs) | Typical duty cycle | Where problems show up first* |

|---|---|---|---|---|---|

| On-Highway | DT12-HL | 1,650 | 80,000 | Linehaul / weight-sensitive | Clutch wear, learn failures, light air leaks |

| On-Highway | DT12-H | 2,050 | 140,000 | General freight | Split pin wear, countershaft brake failures |

| On-Highway | DT12-HE | 2,250 | 160,000 | Downsped fuel-miser spec | RPM flare, harsh skip-shifts under load |

| Vocational | DT12-VL | 1,650 | 80,000 | Mixers / bulk haulers | Heat-soaked oil, slow/failed calibrations |

| Vocational | DT12-V | 2,250 | 140,000 | Construction / utility | Air contamination, stuck solenoids |

| Vocational | DT12-VX | 2,500 | 275,000–330,000 | Heavy haul / logging | High-torque clutch and range-shift stress |

*Pattern notes based on field trends, not absolutes.

2. Where the DT12 actually breaks; inside the case

Split rod jams that kick you into neutral

Detroit’s early split rod design ran a bare steel rod straight through the aluminum housing. No bushing. No sleeve. Once that bore wears, the rod starts to tilt or stick, usually after cold soak. The shift aborts, and the dash lights up with a no-gear warning before you’ve even cleared the off-ramp.

The sticking doesn’t always throw a hard fault. Some units ghost into neutral, then re-engage once temps come up. But the wear only gets worse. The TCM reads shift travel errors, clutch zero points drift, and learn attempts start failing in sequence.

Detroit’s fix came later: a hardened steel bushing and a split rod with three flat faces. The update works, but only if the housing is reamed dead-on and the bushing pressed clean. Rushed installs or skipped reaming cause binding all over again.

Countershaft brake failures that hang the gear change

The countershaft brake forces the shaft to stop spinning between shifts. If it slips, the TCM waits for a speed match that never comes. You get an RPM flare, a long pause, or a full shift abort.

In the field, this shows up most on DT12-H and HE boxes under load, usually 7th to 8th or 9th to 10th, especially when downsped. Worn friction surfaces, leaking seals, or oil that’s too thin all cut braking torque.

DiagnosticLink tells the story fast: desired vs actual countershaft RPM lags, plus abort counters. If the test times out, and the flare lines up with a range shift, the brake’s toast. Pull the box and rebuild. No reflash saves a slipping brake.

Clutch problems that shut the whole system down

The LuK twin-disc clutch used in most DT12s takes abuse in high torque and start-stop duty. Once the disc faces wear past the zero point limit, the system won’t complete a Clutch Learn. Sometimes it won’t even try. Other times, the clutch sticks engaged, and the truck won’t stop even with your foot on the brake.

The flange on some early LuK discs cracked under load, tossing shrapnel into the clutch pack and locking up the driveline. This triggered safety recalls on certain trucks with early LuK clutch parts.

Failed learns also point to worn springs, stuck actuators, or misaligned install. The TCM measures clutch travel down to the millimeter. If it can’t find the kiss point or full disengagement, you’re not going anywhere. Worst-case: it lets you start moving, then dumps to neutral mid-shift under torque; fast way to lose the driveline or rear.

3. When air takes down the whole transmission

Wet air ruins everything the DT12 touches

The DT12 doesn’t just sip air, it needs clean, dry pressure to move shift rails, actuate the clutch, and complete high-low transitions. If moisture gets in, nothing works right. Leaky seals jam actuators. Frozen lines stall startup. Pressure sensors trip false codes even with a full dash gauge.

The air dryer is the first weak link. If the desiccant’s old or oil-saturated, that contamination feeds straight into the DT12’s reserve tank. From there, it clogs solenoids and fouls the actuator block. The tank doesn’t care if the dash says 120 psi; it needs its own clean pressure, or shift commands stall mid-cycle.

Low pressure codes like SPN 521516 FMI 11 show up when that DT12 tank drops below threshold. A bad check valve, cracked air line, or missing drain routine is usually to blame. Ignore it long enough, and the box skips learns, drops range, or won’t release the clutch at all.

Solenoids don’t fail gracefully, they drag and slam

Every shift runs through a sealed block with air solenoids, pressure switches, and internal logic. If even one sticks or delays, the transmission stutters. Harsh engagement. No movement. Or a hard grab into gear like someone dropped the clutch by hand.

Vocational trucks hit this harder. Start-stop cycles and dusty air lines wear seals fast. When the air pulse drags, the actuator stalls mid-travel. That shows up as delayed engagement from stop or a skipped gear from 3rd to 5th.

Field failures usually tie to a gummed-up solenoid, not a dead one. Cleaning sometimes saves it. Most times, the shift module needs replacing, especially if there’s water intrusion behind the harness. Any hint of rust or oil sheen around the connector means it’s already too late.

Leaking range cylinders throw gear shifts out of whack

The range cylinder sits on the back half of the case and runs high-low transitions. If the internal O-rings wear or the ports get crossed during service, the actuator can’t complete the shift fast enough. That logs aborts and blocks future learns.

Once those O-rings leak, you’ll see pressure loss during learn routines, especially when the countershaft brake test fails. The air holds just long enough to start the move, then loses pressure. The TCM sees that as a position fault and dumps the shift.

Post-service cross-plumbing is another repeat offender. It’s not always obvious. But if a truck comes out of the shop shifting fine in low range and hanging or skipping in high, start tracing the lines. Mismatched ports won’t show a code, they just break the behavior.

4. The fault codes that make or break a DT12 diagnosis

These SPNs don’t lie, when to trust the dash

| SPN | FMI | Dash symptom / message | Likely root problem area |

|---|---|---|---|

| 521049 | 7 | Drops to neutral, won’t finish shift | Split rod binding, worn bore or bushing |

| 520970 | 7 | Clutch won’t release, gear won’t grab | Air leak at actuator, warped clutch plate |

| 520982 | 13 | “Clutch learn failed” | Worn disc, bad kiss point, actuator error |

| 521487 | 3/4/5 | Range or gear position sensor faults | TCM connector corrosion, broken lock tab |

| 521516 | 11 | “Trans air pressure low/out of range” | Leaking range cylinder, bad dryer/tank |

| 521001 | 0/1 | Clutch zero point out of spec | Severe wear, misinstall, learn abort |

| 521222 | 19 | “No comm. with CPC” or sudden neutral | CAN harness fault, bad grounds, wet SAM |

These are the codes that matter. Not every ghost fault or pending error means a teardown. But when these show up, they’ve got teeth. They flag real-time failures that won’t go away with a reset or reflash.

Split pin codes surface first during cold starts or under load. Clutch faults escalate from chatter to no-shift conditions within weeks. Range faults tied to SPN 521487 almost always lead back to wiring or corrosion at the TCM or SAM. If you skip inspecting the 21-pin connector, expect the problem to come back mid-run.

When “no gear” is just a broken wire or flooded module

Loose connector locks let the TCM vibrate just enough to trigger a dropout. The system sees sensor loss and defaults to neutral as a fail-safe. No burn. No grind. Just a dead truck that starts working again after a shutdown, and throws techs into parts-swap mode.

Moisture inside the SAM Cab module causes even weirder faults. Tilt sensor errors. Gear position skips. CAN timeouts with no visible wire damage. These trucks often pass static tests, then throw a fault mid-grade or mid-dock cycle when vibration and temperature stack up.

Every tech has reset a DT12 with a battery pull. But that’s not a fix. If the issue is a corroded CPC pin or a rubbed harness behind the air tank, the failure resets every trip. Shops that don’t load-test the power feeds and grounds end up chasing the same code six times.

When software panics and pulls the transmission offline

Shift aborts don’t always mean broken hardware. The TCM and CPC talk constantly, syncing torque cuts, brake tests, and actuator travel. If the numbers don’t match, too slow, too far, too out of range, the software throws an abort and locks the shift.

Clutch learns that fail by more than spec get flagged as SPN 520982 FMI 13, especially if the kiss point can’t be hit in three passes. That’s not a one-off. It means the actuator can’t find the disc edge and assumes it’s gone.

Reflash only helps if the learn still runs. If shift commands stall at the same spot every time, and air and wiring check out, you’re hiding a deeper issue. Usually a split rod, cracked flange, or reversed airline that the TCM can’t diagnose, but the counters never forget.

5. When clutch learns fail, the whole box goes sideways

What a real Clutch Learn should look like

Every Clutch Learn routine pushes the actuator through full travel, confirms zero point, hits the kiss point, and logs range. If it doesn’t hit all targets, the DT12 throws a fault or stays locked out of gear. No shortcut resets it.

Preconditions matter. Battery voltage, air pressure, fluid temp, if any of these miss target, the learn skips steps or fails mid-cycle. Some shops try to run it cold or on a weak battery, then blame the box when it quits halfway through.

A full learn should finish clean, without driver input or pause. If it hangs on one gear, stalls on the brake test, or loops the clutch sweep more than twice, it’s not a programming issue. It’s hardware pushing past spec.

What failed learns are actually telling you

When the learn logs a max distance error, the clutch isn’t just worn, it’s out of range. The actuator can’t reach full throw, or the disc is warped enough to throw the kiss point off the map. Keep forcing it and the software locks out all further calibrations.

Range learn failures don’t always mean internal failure. Most show up from swapped or misrouted airlines after a shift module swap. When high/low actuation hits the wrong port, it stalls on brake release or mid-range transition. The TCM doesn’t know which gear it’s in, and won’t guess.

Abort counters tell the story. If the same step fails three runs in a row, you’re past tuning. The clutch, actuator, or plumbing’s bad. Shops that clear codes without checking counters send the truck back out for the same failure two days later.

Install mistakes that keep causing learns to fail

A bad install triggers more learn faults than worn parts. If the battery gets pulled mid-program, if the box isn’t propped evenly, or if the harness pins don’t seat clean, expect cascading issues.

Old abort counters stick unless cleared manually. Some techs skip that step, run the learn, and wonder why it fails early. They’re not testing a clean state. They’re testing against five past failures.

Final road tests matter. Shops that skip loaded test drives miss real-world conditions where the DT12 slips, clunks, or drops gear. The learn may pass in the bay, but fall apart under grade, heat, or torque.

6. What real DT12 maintenance looks like when uptime matters

The 600,000-mile interval is a marketing myth

Detroit’s official oil interval claims stretch up to 600,000 miles on highway. Few real-world trucks make it past 200,000 without plug fuzz or shifting issues. Downsped linehaul, vocational haul, and heavy start-stop fleets all grind that number down.

Shops pulling drain plugs early are finding metal on magnets and wear patterns around 150,000. The oil breaks down, friction ramps up, and fine debris moves through the shift solenoids and pump. Once that starts, pressure control gets sloppy and shift timing suffers.

Mixing oils or using spec-incompatible blends (outside MB 235.11 or MB 235.16) leads to chatter, internal glazing, and premature wear on synchronizers. There’s no gray area, grab the wrong drum off the wall, and the learn starts failing within weeks.

| GCW & duty cycle | OEM interval (miles) | Practical interval (miles) | Why shorter is smarter |

|---|---|---|---|

| ≤ 80,000 lbs, light duty | 600,000 | 150,000–200,000 | Metal on plugs, protects pump & solenoids |

| > 80,000 lbs or mixed duty | 400,000 | 100,000–150,000 | Higher shear, hotter oil, more load cycles |

| Vocational / severe duty | 400,000 | 75,000–100,000 | Dust, shock loads, constant range shifts |

Moisture and tanks cause more failures than the gears do

The DT12 air circuit depends on clean, dry pressure from a dedicated air tank, not just the dash system. That tank feeds clutch actuation, range shifts, and learn routines. Water or oil in that line shuts it all down.

Desiccant cartridges should be swapped every 30,000–40,000 miles in mixed-use or vocational trucks. But most fleets skip it. What follows is oil carryover into the shift module, rust around the solenoids, and stuck actuators mid-cycle.

Warning signs: faint hissing behind the trans after shutdown, water spitting from the reservoir, or low pressure codes on a full dash gauge. A soap bottle and manual drain catch most early, but shops that rely on gauges alone miss the contamination until it’s jammed the module.

The fleets hitting 1 million don’t guess, they schedule everything

Fleets keeping DT12s alive past 500,000 are running predictive checks, not just mileage-based PMs. Early trucks get preemptive split rod updates at the first sign of shift flare. Every learn is logged. Every air system gets drain tests and sensor cross-checks before a fault ever logs.

Techs who touch DT12s are trained to start at the harness. Pin tension, routing checks, power feed voltage, it’s all part of the standard inspection, not a diagnostic fallback. If the 21-pin TCM connector shows movement or moisture, it gets cleaned or replaced, period.

This isn’t excessive. It’s the baseline. Fleets that treat the DT12 like a regular manual or slap-box automatic end up parked with “NO GEAR” and a six-week parts wait. Fleets that track solenoid timing, control line integrity, and fluid analysis keep moving.

7. When recalls hit and remans double-fail

Range detent recall jammed more than just gears

In 2017, German-built DT12s shipped with an extra detent screw in the range housing. That screw wasn’t supposed to be there. It restricted range movement under load and locked the actuator mid-travel. Shifts failed. Some trucks couldn’t reach highway gears.

Recall 17V-730 pulled those trucks back for an in-frame fix. Techs had to remove the plug, re-torque the spring cap to 100 N·m, and verify range actuation through DiagnosticLink. The fix worked, but only when techs caught every affected VIN. Missed units kept failing under grade with no code, just dropout.

This wasn’t a calibration issue. It was hardware jammed by a screw that never should’ve cleared final build.

LuK clutch failures pushed trucks into unsafe territory

Certain 2021 Cascadias with TM2020 variant DT12s and LuK clutches had a deeper problem, flange cracking under heat. Once the stamped steel let go, metal punched through the disc face and jammed the pressure plate. Result: the clutch wouldn’t disengage.

Trucks either kept rolling when they should’ve stopped, or wouldn’t come out of gear at all. Drivers lost control during low-speed maneuvers and couldn’t complete shifts in tight yards or docks.

Recall 20V-742 forced full clutch and pressure plate replacements. No workaround. If your DT12 has early LuK hardware and you’re seeing stiff pedal feel or no-move events from stop, the safest bet is pulling the pack before it locks up again.

Reman DT12s weren’t all built equal

Detroit’s Field Service Campaign 18M4 flagged reman units built before September 2017. Too many came back with shift failures, metal on plugs, and aborted range transitions, same issues the rebuild was supposed to solve.

Internal inspections showed range housing misalignment, skipped bushing updates, and no split rod fix in units labeled “ready.” The recall forced shops to drain and inspect all suspect boxes. If metal showed on the plug, the unit was pulled, again.

Fleets buying remans without demanding full update logs are taking a risk. If the split rod still runs bare aluminum, or the solenoids test slow under pressure, it’s not reman, it’s just reused.

8. When DT12 trouble shows up in the seat, not the code

Sudden neutral, no gear, and dead-stop failures

Cold starts reveal more about a DT12 than a scanner ever will. If the box drops into neutral on startup, takes forever to grab a gear, or clicks through shifts without moving, the issue’s likely air, split rod, or clutch travel.

Split rod sticking shows up worst after cold soak. You’ll hear the click, feel the delay, then nothing, just a dash message and a truck that won’t move until heat frees the bushing. Some will briefly engage and then slip to neutral as soon as torque builds.

Drivers logging “No Gear” with no vibration, no sound, and no drivetrain bind are often seeing protection mode. The CPC sees an invalid signal, pressure drop, sensor dropout, range stall, and cuts gear hold to prevent damage. If it recovers after a shutdown, start with air or wiring, not the box.

Jerk, flare, or gear hunt, when confidence breaks before hardware does

Skip-shifts and RPM flare hit hardest when the countershaft brake starts to fade. Between 7th and 9th under load, the revs jump, gear hangs, and the torque never comes back clean. From the seat, it feels like a slipping clutch. It’s not. It’s a shaft the brake couldn’t slow in time.

Harsh downshifts into stop signs or low-speed creeps often come from poor learns, actuator lag, or air solenoid drag, not broken parts. If it feels like the box slammed a gear instead of easing in, check for aborted brake test or dirty solenoids, not gear tooth damage.

The moment drivers stop trusting the shift logic, when they feather throttle because they expect a slam, that’s when driveline damage starts. Confidence drops, revs get inconsistent, and the software fights the operator instead of assisting.

Hill starts and dock creep turn glitchy without driver training

Low-speed inching is where most drivers blame the DT12 first. If the truck bucks while backing, rolls during hill starts, or lunges with trailer slack, it’s usually not a failure, it’s the clutch control logic trying to protect the pack.

Drivers trained on full autos stomp the throttle or brake, forcing the TCM to clutch in and out fast. That burns the pack and shortens actuator life. The DT12 expects gentle throttle to hold torque, and minor brake release to re-engage. Miss those cues, and the truck jerks.

Some fleets dial down torque limits at low speed to preserve hardware, but that guts response and worsens the bucking. Fixing the feel means retraining how throttle and brake control engage. Skip that, and the behavior gets labeled a “failure,” when it’s baked into the tune.

9. How the DT12 compares against other AMTs

Where Detroit wins and loses beside I-Shift and Endurant

| Feature / Factor | Detroit DT12 | Volvo I-Shift | Eaton Endurant |

|---|---|---|---|

| Layout | 12-spd AMT, pneumatic clutch & shift | 12-spd AMT, pneumatic clutch & shift | 12-spd AMT, lightweight design |

| Oil Interval (spec) | Up to 600,000 miles | Around 500,000 miles | Up to 750,000 miles |

| Known Weak Spots | Split rod, countershaft brake, solenoids | Range cylinder, legacy clutch logic | Seals, coolerless early units |

| Strengths | Deep DD13/DD15 integration, V/X options | Smooth shift feel, favored by drivers | Long drain interval, lightweight case |

| Failure Drivers | Wet air, extended oil cycles, bad grounding | PM lapses, software neglect | Fluid neglect, heat, seal failures |

The DT12 leans on tight engine-trans integration. IPM logic works hand-in-glove with DD13 and DD15 torque mapping, squeezing fuel by the gallon when tuned right. But if air quality drops or the wiring corrodes, it trips itself before damage hits. That saves driveline life, but leaves trucks stuck unless the shop knows where to look.

Volvo’s I-Shift wins on shift feel. The seat feedback is smoother, the creep logic more intuitive, and driver comfort ranks higher in fleet surveys. But it’s pickier about software updates and older clutches run longer than they should before showing faults.

The Endurant was built lean. It’s lighter, cleaner, and runs longer between services. But early no-cooler units suffered from thermal cycling, especially on grades. Once seals harden or expand unevenly, pressure control falls off, and shifts drag.

What the DT12 does right when fleets keep it sharp

Downsped DD15 setups built around the DT12 pull consistent fuel savings, especially with eCoast, terrain mapping, and smart cruise tuned correctly. Long flat runs give this system the edge. On hills, it needs more brake timing finesse, but the logic still holds torque tighter than a foot-heavy driver ever could.

Vocational variants (DT12-V, VXL) take that same logic and bulk it up. The range case gets heavier bracing. The oiling system gains direct feed across the gear mesh. These units can survive mixers, dump cycles, and quarry runs, if air systems are kept spotless and learn routines aren’t skipped.

Where this box earns its keep is in fleets that track control logic, clear counters before each PM, and retrain drivers to modulate inputs instead of jabbing. Do that, and failures drop. Skip it, and even a clean truck won’t calibrate right.

What happens next: tighter integration, no room for lazy diagnostics

Detroit Assurance already pulls shift data, throttle control, radar input, and braking events into one loop. The DT12 is becoming less of a standalone and more of a drivetrain node. Active safety, predictive cruise, and future EV tie-ins all depend on the same logic bus, and the same clean signals.

This means techs can’t just check fluid or actuator pressure. They’ll need to scope wiring, validate CAN timings, and log software logic steps. If the CPC doesn’t see agreement between modules, the truck drops to neutral or locks out gear entirely, no warning, no reset.

Fleets that treat the DT12 like a dumb gearbox will keep parking trucks with full tanks and no faults. The ones that treat it like the brainstem of the powertrain? They’ll keep running when everyone else is waiting on parts.

Sources & References

- DT12 On-Highway Series: Automated Manual Transmissions – Demand Detroit

- detroit® – dt12 – Freightliner

- What are SA SPN FMI – Beginners guide to fault codes – OTR Performance® Inc.

- DETROIT™ DT12™ TRANSMISSION – Southport Truck Group

- DT12 Vocational – Demand Detroit

- Detroit Expands Vocational Transmission Lineup with New DT12-VL

- DT12 Transmission Issues? Here’s What Fails Most Often 🛠️ – YouTube

- DT12 Transmission Services | Certified Repair & Maintenance Experts

- DT12 TRANSMISSION ISSUES, STUCK IN NEUTRAL | Page 2 | TruckersReport.com Trucking Forum

- 18 TS-2Rev Mar 11, 2019 TO: Dealers Only FROM: Service Systems Development SUBJECT: Detroit™ DT12™ Split Rod Bushing Re – nhtsa

- DT12 TRANSMISSION ISSUES, STUCK IN NEUTRAL | TruckersReport.com Trucking Forum

- New driver – transmission randomly pops into neutral : r/Truckers – Reddit

- FIELD SERVICE CAMPAIGN BULLETIN – nhtsa

- Symptoms of a Bad Transmission Shift Solenoid – AutoZone

- Signs of a Failing Shift Solenoid – Tier One

- How to Tell If Your Transmission Solenoid Is Failing

- 9 Bad Shift Solenoid Symptoms: Causes, Diagnosis & Repair Guide | ANCEL

- Detroit DT12 shifting problems | TruckersReport.com Trucking Forum

- Detroit DT12 shifting problems | Page 2 | TruckersReport.com Trucking Forum

- Dt12 transmission air problems | TruckersReport.com Trucking Forum

- Additions, Revisions, or Updates DiagnosticLink users: Please update the troubleshooting guides in DiagnosticLink with this newe

- Detroit DT12 (2013-2020) Fault Codes List – Diesel Repair

- DT12 trans/clutch relearn procedure… – nhtsa

- Dt12 Transmission : r/DieselTechs – Reddit

- Mercedes / Freightliner DT12 – Camerota Truck Parts

- Dt12 automatic transmission issue please help | TruckersReport.com Trucking Forum

- Additions, Revisions, or Updates 06 14-18 3 06 14 … – Collage (1-9)

- Detroit™ Automated Transmission Fluid Change and Magnetic Plug Cleaning – Public Technical Literature

- RK Detroit DT12 Transmission Full Complete – Repair Manual | PDF – Scribd

- PM Class C Full Preventive Maintenance Checklist for Freightliner Highway Trucks

- D20M2 DETROIT TM2020 Transmission Replacement – nhtsa

- SAFETY RECALL BULLETIN – nhtsa

- Recall Campaign – nhtsa

- DT12 vs 13 speed | Page 8 | TruckersReport.com Trucking Forum

- Which for my 1st truck Volvo I Shift or Freightliner auto? | Page 4 – Truckers Report

- Detroit transmission dazzles in debut – Truck News

- Top Diesel & Electric Long-Haul Trucks of 2025

- Eaton Endurant 12-Speed Transmission: The Ultimate Guide to …

- Who Makes the Most Dependable Vehicles in 2025? – Work Truck Online

- DOT NHTSA ODI Document

Was This Article Helpful?