Picking the right cylinder heads can make or break your engine build, especially when balancing compression, airflow, and cost.

The 317 and 243 heads, both part of GM’s LS-series lineup, offer unique strengths for different setups, but choosing the wrong one could leave you with underwhelming results or added expenses.

Whether chasing boosted power or maximizing naturally aspirated performance, this guide will unpack the details you need to make the right call and get the most out of your build.

1. Background and Typical Applications

317 Heads

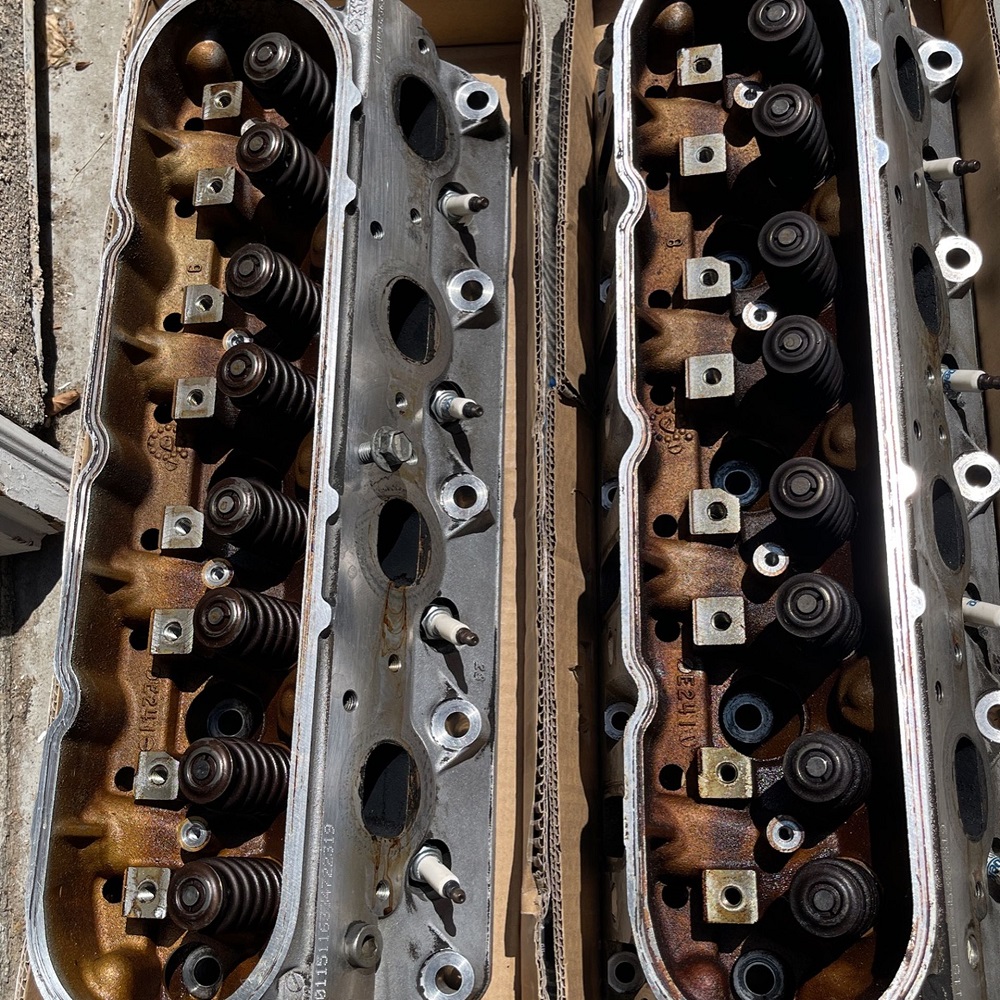

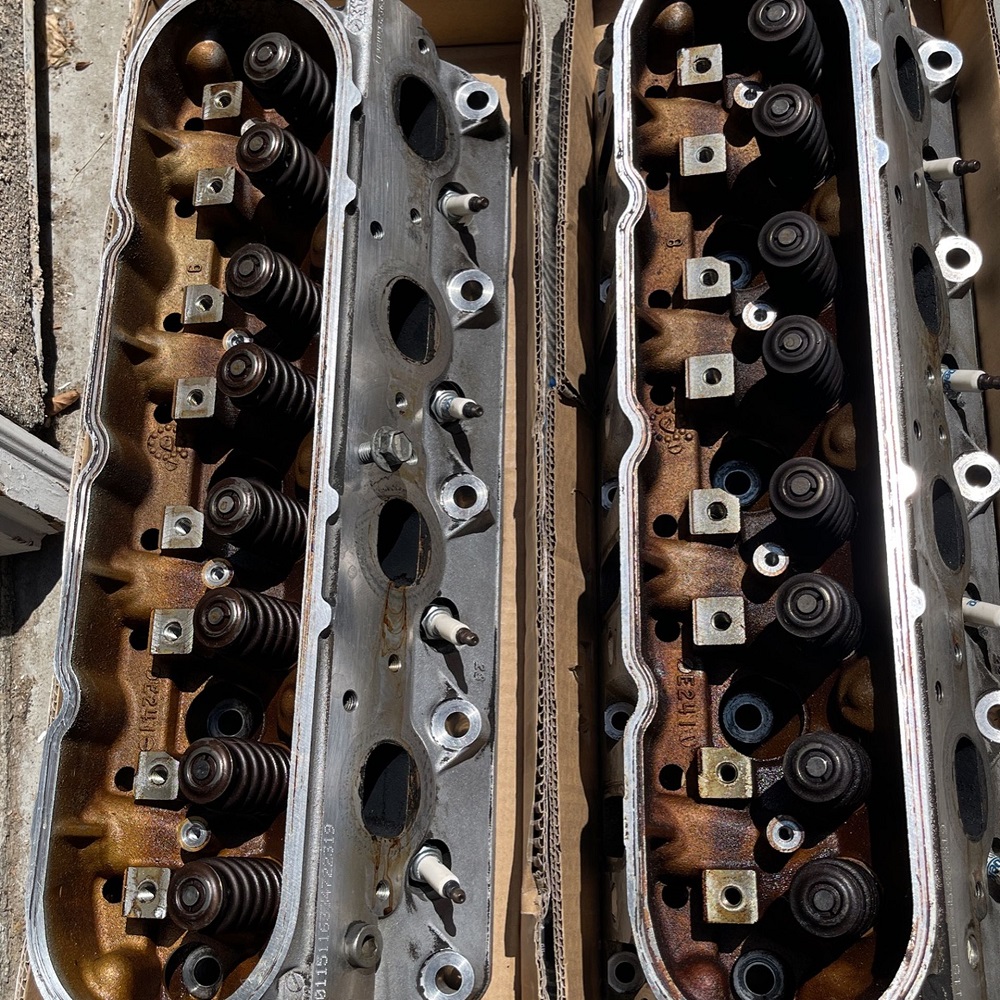

These castings often appear on truck and SUV engines, including the LQ4 and LQ9 platforms. Their combustion chambers measure around 71 to 72 cubic centimeters, naturally lowering compression when used on most LS short blocks.

That design works well for builds that plan to add boost later, as the bigger chamber can help guard against detonation under higher cylinder pressures.

Many truck owners find 317 heads at reasonable prices in local salvage yards, making them an attractive option for those interested in a budget-friendly upgrade.

They flow similarly to more desirable LS castings, so a set of ported 317 heads can support solid horsepower numbers.

The main trade-off is that the larger chamber may feel soft in naturally aspirated setups unless you choose pistons or a head-milling approach that raises compression backup.

243 Heads

These heads initially appeared on the LS6 Corvette Z06 from 2001 through 2004. Their chamber volume is around 64 to 65 cubic centimeters, which bumps up compression on the same short block compared to 317 heads.

Enthusiasts often prize 243 castings for their ability to unlock extra horsepower in a naturally aspirated application without major block modifications.

Because the 243 design is based on a performance-oriented engine, it delivers strong mid- and high-RPM flow. This makes it a favorite for street/strip cars hunting for better throttle response and a bit more top-end power.

However, their popularity and limited supply can drive prices higher on the used market, especially if the set is in good condition and includes upgraded valves or hardware.

2. Combustion Chamber and Compression Ratio

317 Heads

The larger 71-72 cc combustion chambers on 317 heads make them well-suited for forced induction builds. Lowering the compression ratio reduces the risk of detonation, even when running on pump gas with a supercharger or turbo. This extra safety margin can be pivotal in high-boost setups, where cylinder pressures climb rapidly.

However, this lower compression comes with a trade-off. In naturally aspirated applications, the reduced cylinder pressure can soften low-end torque and overall throttle response.

To counteract this, some builders opt to mill the heads or use high-compression pistons to regain the lost compression, though these adjustments add cost and complexity to the build.

243 Heads

With a smaller 64-65 cc combustion chamber, 243 heads naturally raise the compression ratio on most LS short blocks.

This increased compression boosts power and efficiency, making it ideal for naturally aspirated builds focused on maximum output per cubic inch.

The smaller chambers also promote better thermal efficiency, leading to more complete combustion and improved performance.

The downside of the higher compression is its sensitivity to tuning and fuel quality. Engines with 243 heads often require premium fuel to avoid knock, and if forced induction is introduced, careful tuning becomes essential to prevent issues under boost.

Some builders add thicker head gaskets or lower-compression pistons to balance the higher cylinder pressures in these scenarios.

3. Port Flow Characteristics

317 Heads

The 317 heads share nearly identical intake and exhaust port dimensions with the 243 castings, which allows them to support respectable power levels.

Their cathedral port design is known for efficient airflow and good velocity, making them a versatile option for naturally aspirated and boosted applications.

However, the larger combustion chambers can limit their effectiveness in naturally aspirated builds. Lower cylinder pressures from reduced compression mean the engine may not fully take advantage of the port flow potential, especially in mid- to high-RPM ranges.

For enthusiasts looking to optimize 317 heads, porting and milling are common upgrades that can significantly enhance their performance and restore lost compression.

243 Heads

The 243 heads are renowned for their excellent airflow characteristics, particularly in mid- to high-RPM powerbands.

They feature cathedral ports designed for optimal intake velocity and potent exhaust scavenging, contributing to their ability to produce impressive naturally aspirated horsepower.

These heads shine in builds that prioritize high-performance, naturally aspirated setups. Their superior port flow allows them to maintain strong power delivery across a wide RPM range.

However, in mild or low-RPM truck applications, the aggressive port design can sometimes be excessive, prioritizing top-end power over low-end torque.

The performance potential of 243 heads often justifies their premium price, especially when paired with complementary upgrades like a performance camshaft or higher-flow intake manifold.

4. Typical Power Potential and Tuning

317 Heads

The 317 heads are highly regarded in the world of forced induction. Their larger combustion chambers create lower static compression ratios, making them ideal for handling high boost levels from superchargers, turbochargers, or nitrous systems.

This characteristic allows for more aggressive tuning and safer operation under high cylinder pressures, especially on pump gas.

For naturally aspirated builds, the power potential of 317 heads can be somewhat limited unless compression is compensated for through other means, such as high-compression pistons or head milling.

Without these modifications, the engine may lack the snappy throttle response and low-end torque that high-compression setups deliver.

However, when ported and paired with supporting modifications, 317 heads can still flow well enough to support impressive horsepower numbers, often exceeding 500 horsepower with the proper setup.

243 Heads

The 243 heads are synonymous with high-performance, naturally aspirated LS builds. Their smaller chambers naturally raise compression, allowing for more efficient combustion and increased power output without additional modifications.

With the right camshaft and intake manifold, 243 heads can help unlock significant gains in horsepower and torque, particularly in mid- to high-RPM ranges.

When tuned correctly, engines equipped with 243 heads deliver excellent throttle response, strong low-end torque, and impressive top-end power.

However, the higher compression ratios these heads produce can make them more challenging to work with in forced induction setups.

Boosted engines with 243 heads require precise tuning, premium fuel, and often stronger internals to handle the added stress of high cylinder pressures.

Despite these challenges, 243 heads remain a top choice for performance enthusiasts who value efficiency and power.

317 Heads

One of the main advantages of 317 heads is their affordability and widespread availability. Commonly found on truck and SUV engines such as the LQ4 and LQ9, these heads are frequently salvaged from junkyards and sold at significantly lower prices than their performance-oriented counterparts.

Their lower demand among naturally aspirated performance enthusiasts keeps prices reasonable, making them an attractive option for budget-conscious builders.

For those planning to add forced induction, 317 heads offer excellent value. Their flow characteristics are comparable to higher-end LS heads, and their larger combustion chambers make them boost-friendly right out of the box.

However, since many used 317 heads come from high-mileage engines, they may require machining—such as valve jobs, resurfacing, or milling—which can add to the project’s overall cost.

243 Heads

The 243 heads, originally designed for performance applications, command a higher price in the aftermarket. Their reputation as a go-to upgrade for LS1, LS2, and other naturally aspirated engines drives demand, especially among enthusiasts looking for an easy compression boost and improved flow.

As a result, clean, used sets of 243 heads often fetch a premium, particularly if they include upgraded hardware like stainless steel valves or performance springs.

Their higher price point reflects their scarcity, desirability, and proven performance capabilities. Whether you’re building a high-performance, naturally aspirated engine or a mild forced induction setup, the investment in 243 heads can pay off in terms of power and reliability.

However, depending on your overall goals, the higher cost of 243 heads might be better spent on other performance upgrades for budget-conscious builds.

6. Common Complaints and Drawbacks

317 Heads

The most common criticism of 317 heads is their lower compression ratio, which can hinder performance in naturally aspirated builds.

Without modifications such as milling the heads or swapping in higher-compression pistons, the reduced cylinder pressure can leave engines feeling underpowered, particularly in low-RPM ranges. This makes them less appealing to builders aiming for maximum power in naturally aspirated configurations.

Another issue with 317 heads is the condition of used sets. Since these heads are often sourced from high-mileage trucks and SUVs, they may show signs of wear, such as valve seat recession, warped surfaces, or worn guides.

While these problems can be addressed with machining, the added cost and effort can diminish their initial price advantage.

Also, some builders find the larger combustion chambers more challenging to work with when trying to achieve a specific compression ratio for naturally aspirated builds.

243 Heads

The primary drawback of 243 heads is their higher cost and limited availability. As a sought-after performance upgrade, these heads command premium prices in the used market, making them less accessible to budget-conscious builders.

Also, clean sets in good condition can be hard to find, especially if they haven’t already been modified or used in demanding applications.

Compression sensitivity is another concern with 243 heads, particularly in forced induction setups. Their smaller combustion chambers create higher cylinder pressures, which demand precise tuning and premium fuel to avoid detonation.

Builders planning to add significant boost must carefully balance their setups, often requiring thicker gaskets or dished pistons to lower compression. This added complexity can make 243 heads less appealing for those who prefer plug-and-play solutions.

Final Thoughts

Choosing between 317 and 243 cylinder heads depends on your engine’s goals and intended use. If you’re building a boosted setup or working with a tighter budget, the 317 heads offer great flow potential and boost-friendly chambers at a reasonable price.

On the other hand, the 243 heads excel in naturally aspirated builds, delivering higher compression, better efficiency, and stronger top-end performance, though they come at a premium.

Both heads have strengths, and the right choice depends on your build’s priorities. Whether you’re chasing horsepower, durability, or affordability, either option can deliver impressive results when matched to the correct application.

Was This Article Helpful?

Thanks for your feedback!

Rami Hasan is the founder of CherishYourCar.com, where he combines his web publishing experience with a passion for the automotive world. He’s committed to creating clear, practical guides that help drivers take better care of their vehicles and get more out of every mile.