When it comes to auto body repairs, selecting the suitable body filler isn’t just a technical decision—it’s about ensuring your vehicle looks great and withstands the test of time.

Bondo and Evercoat have built strong reputations, but understanding their distinctions can help you pick the best one for your needs.

Here’s a breakdown of what you need to know about these two popular brands before you mix, apply, and smooth your way to a flawless finish.

Table of Contents

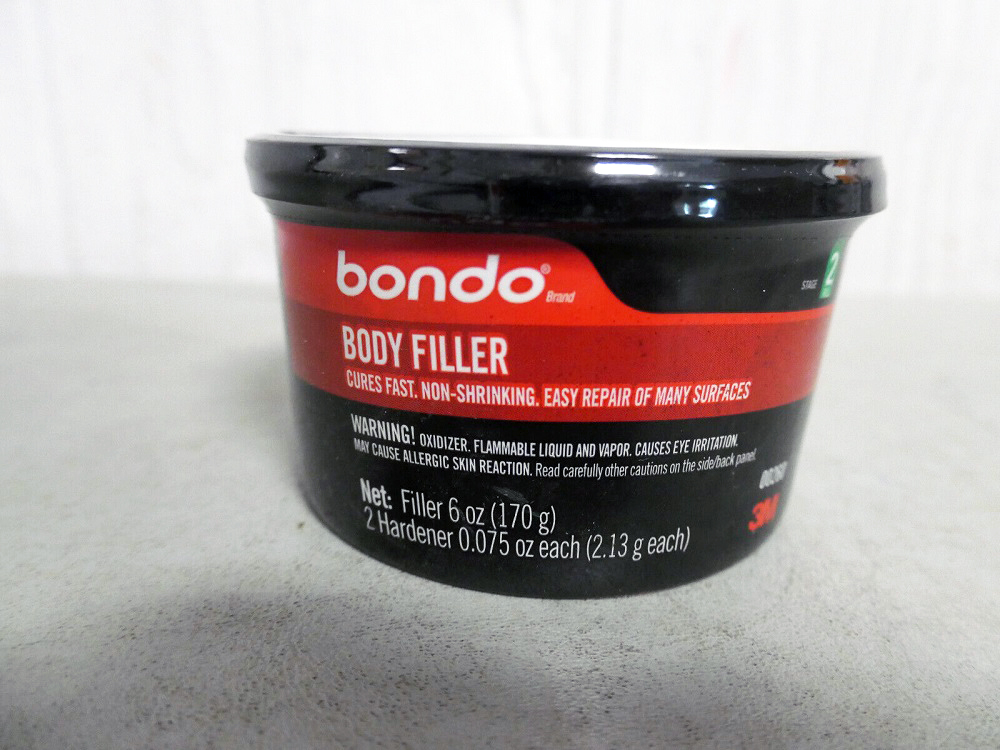

Bondo Body Filler

Bondo, a household name in the auto body repair industry, is known for its quick-curing properties and robust application versatility.

Initially developed for automotive use, it has found its way into various repair tasks, from smoothing over dents to fixing damaged wood.

Evercoat Body Filler

Evercoat, on the other hand, is recognized for its innovative formulations that minimize pinholing and promote a superior finish.

Tailored more towards professional use, Evercoat products often incorporate advanced technologies like microsphere formulas to enhance the quality and durability of repairs.

1. Formulation and Chemical Properties

Understanding a body filler’s formulation and chemical properties is essential for achieving the best results. Here, we discuss the main ingredients and unique characteristics of Bondo and Evercoat body fillers.

Bondo

Main Ingredients and Chemical Structure

Bondo body filler primarily consists of polyester resins, known for their durability and fast curing times. This resin is typically combined with talc, which acts as a bulking agent to give the filler its shape and consistency.

Characteristics Influencing Adhesion and Curing

Bondo’s chemical makeup ensures it adheres well to metal and other materials, making it an excellent choice for various repairs.

Its curing agents are designed to trigger a rapid hardening process, which is why Bondo is favored for quick repair tasks where time is of the essence.

Evercoat

Main Ingredients and Chemical Structure

Evercoat body fillers also use polyester resins but are enhanced with microsphere technology. This includes using glass microspheres that create a smoother, more workable consistency and help reduce the weight of the filled area.

Advanced Technologies (e.g., Microsphere Technology)

The inclusion of microsphere technology in Evercoat fillers not only improves the ease of sanding but also enhances the overall finish.

These microspheres contribute to a lower pinhole occurrence in the final dried product, a common issue in lower-quality fillers.

2. Application Process

The application process for body fillers is critical to achieving a smooth, professional finish. Bondo and Evercoat have specific requirements and tips for optimizing the application to achieve the best results. Here’s what you need to know to apply each product effectively.

Bondo

Mixing Requirements

Bondo body filler needs to be thoroughly mixed with a hardener at a precise ratio, typically 50:1 (filler to hardener), before use.

Achieving a uniform color and consistency is crucial to ensure the filler cures properly and adheres well to the surface.

Application Tips for Optimal Results

• Surface Preparation: Ensure the surface is clean, dry, and free of rust or paint for the best adhesion.

• Mixing Technique: Use a flat surface and a plastic spreader to mix the components to avoid air bubbles, which can weaken the filler.

• Application: Apply the filler in thin layers, building up slowly to the desired thickness. This prevents the creation of air pockets and ensures a more durable repair.

Evercoat

Mixing Requirements

Evercoat fillers also require careful mixing with a hardener, but the ratio can vary slightly depending on the specific product line. Uniform mixing is critical to fully activating the microsphere technology.

Application Tips for Optimal Results

• Temperature Considerations: Evercoat fillers are sensitive to temperature; applying them in a controlled environment can enhance their performance.

• Smooth Application: Evercoat’s smoother consistency allows for a more straightforward application. Spread the filler in even layers to prevent uneven curing and sanding issues later.

• Layering: Like Bondo, applying Evercoat fillers in layers is recommended. Allow each layer to cure slightly before adding the next. This technique helps achieve a flawless finish without sagging or separation.

3. Sanding and Finishing

The quality of sanding and finishing can significantly affect the appearance and longevity of auto body repairs.

Bondo and Evercoat offer unique characteristics that accommodate different needs during the sanding and final finishing stages. Here’s what sets each apart in this crucial phase.

Bondo

Ease of Sanding Post-Application

Bondo is known for its quick curing time, which is beneficial when time is a priority. However, this feature also means it can become quite challenging, which may require more effort during sanding.

It’s advisable to sand Bondo shortly after it cures to avoid excess hardness and difficulty in shaping.

Final Finish Quality

Once sanded, Bondo can provide a very smooth surface if done correctly. It’s essential to use the correct grade of sandpaper and a proper sanding technique to minimize scratches and achieve a paint-ready surface.

Bondo is effective for more extensive repairs as it tends to be less prone to shrinkage compared to other fillers.

Evercoat

Ease of Sanding Post-Application

Evercoat’s advanced formulations with microsphere technology make it easier to sand. The microspheres create a more pliable cured filler, which can be shaped and smoothed with less effort than Bondo.

This property makes Evercoat particularly popular among professionals seeking a flawless finish.

Final Finish Quality

Evercoat products are designed to minimize pinholing, which is crucial for a top-quality finish—the smoother consistency of the filler after curing leads to a surface that requires minimal touch-ups before painting.

It’s particularly suited for high-end finishes where detail and perfection are paramount.

4. Performance and Durability

Performance and durability are essential when evaluating body fillers, as they directly impact the longevity and aesthetics of auto body repairs.

Bondo and Evercoat each have their strengths in different environmental conditions and usage scenarios. Here’s a closer look at how each brand holds up over time and under various stresses.

Bondo

Durability Over Time

Bondo has established a reputation for its robust durability once fully cured. It adheres firmly to a variety of surfaces and can withstand considerable physical impacts without cracking or flaking.

This makes it an ideal choice for small—and large-scale repairs, particularly in areas that may experience frequent stresses.

Suitability for Different Environmental Conditions

Bondo’s chemical composition enables it to perform well in diverse environmental conditions. It effectively resists moisture and temperature changes, which helps prevent the repaired area from deteriorating prematurely.

However, it’s essential to ensure that Bondo is correctly sealed with high-quality paint to maximize its resistance to weather and ultraviolet light.

Evercoat

Durability Over Time

Evercoat fillers are known for their flexibility, contributing to their durability, especially in areas prone to expansion and contraction.

The flexibility ensures the filler remains intact and bonded to the substrate, reducing the risk of cracking over time. This feature is particularly beneficial in climates that see wide temperature swings.

Suitability for Different Environmental Conditions

Thanks to the advanced formulation, including microsphere technology, Evercoat products are highly resistant to shrinkage and absorb less moisture than other fillers.

This makes them exceptionally suitable for humid or wet climates where moisture resistance is critical. Their performance is consistently reliable, maintaining integrity and appearance over long periods.

5. Cost and Value

Evaluating the cost and overall value of Bondo and Evercoat body fillers is essential for professionals and DIY enthusiasts.

The price per unit and the performance value they deliver are key factors in deciding which brand to choose for specific auto body repair needs.

Bondo

Pricing per Unit

Bondo is generally known for being cost-effective, which makes it a popular choice for those on a budget.

Bondo products’ affordability does not significantly compromise their quality, making them a solid option for a wide range of repair jobs, from minor dings to larger dents.

Overall Value Based on Performance and Longevity

Bondo’s value extends beyond its initial low cost. Its durable nature and strong adhesion properties offer great long-term value.

For typical repair jobs where a high-end finish is not the primary concern, Bondo provides a reliable, economical solution that lasts.

Evercoat

Pricing per Unit

Evercoat products are typically priced higher than Bondo. This reflects their specialized formulations, such as those incorporating microsphere technology, designed to achieve superior finishes and more accessible sanding capabilities.

Overall Value Based on Performance and Longevity

Despite its higher initial cost, Evercoat’s overall performance benefits are seen. The fillers are less prone to issues like pinholing and are easier to sand, which can reduce labor time and effort significantly.

The durability and exceptional finish quality also mean less rework and maintenance over time, potentially offsetting the initial higher investment.

Conclusion

Choosing the suitable body filler—whether Bondo or Evercoat—depends mainly on specific project requirements and personal preferences.

Bondo offers excellent durability and cost-effectiveness, making it suitable for various repair jobs. Evercoat, while more expensive, excels in providing a superior finish and easier sanding, making it ideal for high-end repairs.

Users can pick the product that best meets their needs by considering durability, environmental conditions, and budget, ensuring quality and value in their auto body repair projects.