If you’re battling rust on your vehicle or other metal surfaces, you’ve likely come across Eastwood Rust Encapsulator and POR-15 as top competitors for the job.

Table of Contents

Eastwood Rust Encapsulator

Eastwood Rust Encapsulator has carved a niche in the rust prevention world. It’s known for its easy application and durable protection against further corrosion. This product works by sealing rusted metal from the air, which is essential to stop ongoing rust.

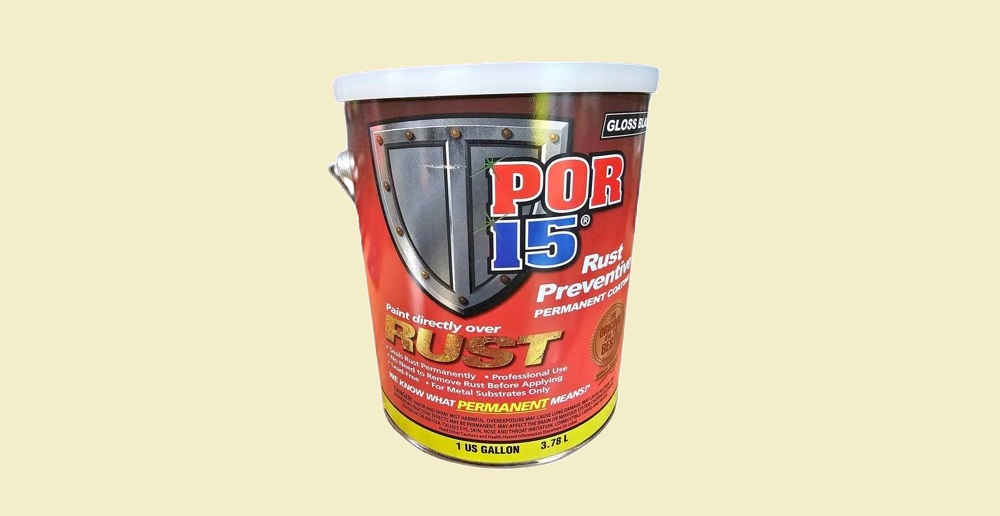

POR-15

On the other hand, POR-15 is often praised for its robustness and ability to prevent rust in highly corrosive environments.

Unlike traditional paint, POR-15 is designed to be applied directly over rusted surfaces, where it hardens to a tough, non-porous coating that moisture cannot penetrate.

Both products promise effective rust prevention, but understanding their differences can help you decide which suits your project. Here’s a straightforward look at these two popular rust treatment options.

1. Chemical Composition

Eastwood Rust Encapsulator

Key Ingredients and Properties

Eastwood Rust Encapsulator includes a mix of resins and additives designed to form a barrier against moisture and oxygen, two elements crucial for rust progression. It is engineered to penetrate rust, bond to metal, and create a non-porous surface.

Mechanism for Stopping Rust

The primary action of the Eastwood Rust Encapsulator is to encapsulate rust. Once applied, it forms a flexible yet tough coating that prevents air and moisture from reaching the metal underneath. This isolation stops the rusting process, effectively preserving the metal in its current state.

POR-15

Key Ingredients and Properties

POR-15 stands out with its moisture-cured urethane composition. This unique formula allows it to strengthen when exposed to moisture, making it particularly effective in humid or wet environments.

The product also contains specific additives that enhance its ability to adhere to rusted surfaces without requiring extensive surface preparation.

Mechanism for Stopping Rust

POR-15 works by creating a rock-hard, impermeable coating over rusted areas. Its moisture-curing property means that the presence of humidity improves its adhesion and durability.

Once cured, the coating is virtually impervious to water, chemicals, and other corrosive elements, thereby preventing further rust development.

2. Application Process

Eastwood Rust Encapsulator

Surface Preparation Required

For optimal results with the Eastwood Rust Encapsulator, the surface should be clean and mostly free of loose rust and flaking paint.

A simple wire brushing or light sanding is usually sufficient to prepare the surface. However, the product can tolerate minor surface impurities better than most traditional coatings.

Application Method (Brush, Spray, Roller)

Eastwood Rust Encapsulator is versatile in its application methods. Depending on the user’s preference and the job’s specifics, it can be applied using a brush, roller, or spray gun. This flexibility allows for easy use in various settings, from detailed automotive parts to larger surface areas.

Curing Time and Conditions

The curing time for Eastwood Rust Encapsulator can vary based on ambient temperature and humidity. Typically, it dries to the touch in 2-3 hours and cures entirely within 24-48 hours. The product cures faster in warm, dry conditions.

POR-15

Surface Preparation Required

POR-15 requires thorough surface preparation to achieve its best performance. The surface must be free of grease, oil, and loose rust. POR-15 recommends using their specific cleaners and metal prep solutions to ensure the surface is optimally prepared for coating.

Application Method (Brush, Spray, Roller)

Like Eastwood Rust Encapsulator, POR-15 can be applied with a brush, roller, or spray. However, due to its thicker consistency and faster curing time in moisture, careful application is crucial to avoid drips and runs, especially when spraying.

Curing Time and Conditions

POR-15 cures significantly in response to humidity. Depending on environmental conditions, it dries to the touch within 2-6 hours and can be fully cured within 24-72 hours. Higher humidity levels can accelerate the curing process.

3. Effectiveness and Durability

Eastwood Rust Encapsulator

Performance Under Various Conditions (Humidity, Salt, UV)

Eastwood Rust Encapsulator performs well in various environments, including high humidity and salt exposure areas.

It also contains UV inhibitors, which make it suitable for parts exposed to sunlight. These properties ensure the product maintains its protective qualities over time, resisting degradation from environmental factors.

Longevity of Rust Protection

The longevity of Eastwood Rust Encapsulator’s protection typically extends several years, depending on the exposure conditions and proper application.

Regular maintenance and inspections can prolong its effectiveness, especially on surfaces subjected to harsh conditions.

POR-15

Performance Under Various Conditions (Humidity, Salt, UV)

POR-15 is famous for its exceptional performance in severe conditions, including extreme humidity, salt spray, and UV exposure.

It is designed to resist breakdown from chemical and environmental exposure, making it an ideal choice for marine environments and vehicle undercarriage treatments.

Longevity of Rust Protection

One of POR-15’s most significant advantages is its durability. It can provide rust protection for many years without reapplication when applied correctly and under the right conditions. Its ability to create a permanently bonded, hard coating ensures prolonged protection against further corrosion.

4. Suitability and Versatility

Eastwood Rust Encapsulator

Best Uses (Automotive, Marine, Household)

Eastwood Rust Encapsulator is highly versatile and suited for a variety of applications. It’s commonly used in automotive settings for undercarriages, frame rails, and wheel wells where rust tends to accumulate.

Also, it performs well in marine environments and can be used around the home on metal fences, gates, and outdoor furniture, providing a protective coat that withstands the elements.

Compatibility with Other Coatings and Substrates

One advantage of the Eastwood Rust Encapsulator is its compatibility with various substrates and top coatings.

It can adhere to both bare and rusted metal, and once cured, it can be top-coated with most types of paint without requiring a primer. This makes it an excellent base layer for further customization and protection.

POR-15

Best Uses (Automotive, Marine, Industrial)

POR-15 is particularly effective in automotive applications, especially in areas prone to intense rust, such as frames, floorboards, and exhaust systems.

It’s also well-suited for industrial applications where metal needs protection in corrosive environments, such as factories and warehouses. POR-15 is advantageous for coating bulkheads, boat hulls, and other components exposed to saltwater.

Compatibility with Other Coatings and Substrates

POR-15’s strong adhesion properties allow it to bond effectively with any metal surface, including heavily rusted areas.

However, POR-15 must be used as a base layer beneath compatible top coats, as exposure to UV light without a proper top coat can degrade the finish. Its compatibility extends to various metals, providing a robust base for additional protective coatings.

5. Cost Comparison

Eastwood Rust Encapsulator

Price Per Unit (e.g., per quart or gallon)

Eastwood Rust Encapsulator is competitively priced, making it an accessible option for amateur and professional restorers.

The cost per quart typically ranges, making it a cost-effective solution for smaller projects or those needing to treat multiple areas without a significant financial outlay.

Coverage Area Per Unit

The coverage area of Eastwood Rust Encapsulator is impressive, with a single quart covering approximately 50 square feet.

This high coverage rate makes it an economical choice, as fewer products are needed to cover larger surfaces, further stretching the value of each purchase.

POR-15

Price Per Unit (e.g., per quart or gallon)

POR-15 tends to be priced higher than Eastwood Rust Encapsulator, reflecting its specialized formula and durability in extremely harsh conditions. The price per quart can be a significant investment, especially for large projects or frequent use.

Coverage Area Per Unit

POR-15 offers an area similar to the Eastwood Rust Encapsulator, with one quart covering up to 96 square feet under ideal conditions.

While the initial cost is higher, the extensive coverage area can justify the expense, especially for long-term projects requiring robust rust protection.

Conclusion

As we’ve seen, both Eastwood Rust Encapsulator and POR-15 offer robust solutions for preventing and treating rust, each with its strengths tailored to different needs and environments.

Eastwood Rust Encapsulator stands out for its affordability and ease of use, making it ideal for everyday projects and minor restorations.

On the other hand, POR-15 offers superior durability in harsh conditions, justifying its higher price with superior long-term protection.

Choosing between them depends mainly on your project’s specific requirements, including environmental factors, the extent of rusting, and budget considerations.

Whatever the project you are working on, both products provide reliable defenses against corrosion, ensuring lasting results and value.