POR-15 Rust Preventive Coating is designed to be applied directly to properly prepped rusted or seasoned metal. Unlike traditional paints, it doesn’t require a dry surface—it actually cures stronger when exposed to moisture, making it ideal for sealing out rust long-term.

Many users wonder if you can apply epoxy primer or paint over POR-15. The answer is yes—but not without proper prep. Once POR-15 has fully cured, most paints won’t stick to its slick surface on their own.

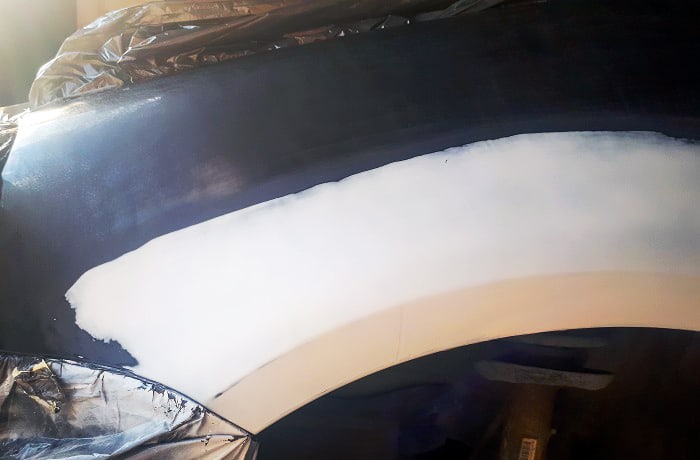

That’s where POR-15 High Build Primer comes in. It’s applied after the Rust Preventive Coating has cured and creates a sandable layer that allows topcoats—like epoxies, urethanes, or enamels—to bond properly. It’s the recommended step if you plan to paint over POR-15 for a clean, durable finish.

✔ Permanently Stops Rust – Trusted by pros and DIYers, POR-15 creates a rock-solid, non-porous barrier that seals out water, salt, chemicals, and grime—ideal for automotive, marine, farm, and industrial gear.

✔ Moisture-Cured for Strength – Unlike traditional paints, this coating cures faster with humidity, forming a hammer-tough, chip-resistant finish that won’t peel or crack.

✔ Built for Harsh Conditions – Use it on metal, wood, fiberglass, bricks, and concrete—perfect for frames, axles, underbodies, trailers, and more.

✔ Part of the 3-Step System – For best results, prep your surface with POR-15 Cleaner Degreaser and Metal Prep, then apply at least two thin coats. Cures to the touch in 2–5 hours and can be top-coated for UV exposure.

✔ Trusted Performance – Known for its long-term durability, POR-15 is a go-to in environments where abrasion, rust, and weather exposure are daily threats.

✔ Preps Metal for Paint – Gently etches bare metal and neutralizes rust while laying down a zinc phosphate layer for unbeatable coating adhesion.

✔ Boosts Coating Performance – Ensures strong chemical bonding with POR-15 Rust Preventive Coating or any paint applied afterward.

✔ Safe, Water-Based Formula – Non-toxic, non-corrosive, and easy to apply by brush, spray, roller, or dip.

✔ Ideal for DIY & Pro Projects – Use on auto parts, outdoor fixtures, fencing, and more to stop rust before it spreads.

How do you spray epoxy primer over POR 15?

The first crucial step to successfully spraying epoxy primer over POR 15 is by thinning the paint formula. You also need to ensure that you are equipped with a good respirator to avoid inhaling harmful paint fumes.

You are also advised to stir the topcoat on the POR 15 Rust Preventive Formula before and during use.

Using a pouring spout, pour a portion of the formula into a separate container and firmly seal the can to avoid ruining the paint. Ensure that the grooves and lid of the container remain clean and free from moisture.

Once the surface is thoroughly cleaned, spread a coat of the POR 15 Top Coat formula and finish with a thin epoxy primer coating.

If possible, get yourself a spray gun when painting epoxy primer over POR 15. This will help you save on time, energy, and costs.

However, you will have to dispose of the gun after use, as the POR 15 formula is quite impossible to clean off. The following are some simple, quick steps that need to be followed when spraying epoxy primer over POR 15:

• Wear personal protective equipment such as respirators, gloves, etc.

• Perfectly mix the POR 15 Rust Preventive Formula using a paint stick.

• With the paintbrush, apply a single thin coat of the formula to all areas.

• Allow the painted area to dry between 2-6 hours, and then apply a second coat of the rust preventive formula.

✔ Durable, Rust-Resistant Finish – Designed to go directly over bare steel, aluminum, body filler, or fiberglass, this 2K epoxy primer lays down a tough, corrosion-blocking base that sets the stage for long-lasting paintwork.

✔ No HVLP Needed – Get professional spray results without a gun. The German-made nozzle delivers a smooth, wide fan pattern, mimicking pro paint equipment.

✔ Built-In 2K Catalyst – Features an internal hardener system for enhanced adhesion and chemical resistance. Activates with a simple button press, offering up to 48 hours of pot life once triggered.

✔ Coverage & Shelf Life – Each 12 oz can covers up to 16 square feet, with an impressive 3-year shelf life unopened.

✔ Trusted by Pros – Backed by Eastwood’s reputation for high-performance restoration tools, with lifetime tech support and a 60-day limited warranty.

What surfaces can epoxy primer be sprayed over?

Epoxy primer is a non-porous, high-bonding sealer with numerous pros when sprayed on certain materials and situations.

For satisfactory results, you should take note of what surface you are applying it on. Below are some insights on the materials and situations epoxy primer works best:

1. Over Bare, Clean Metal

Epoxy primer is perfect for coating bare, clean metal and prevents the risk of corrosion or moisture developing.

It usually works by completely sealing oxygen from the metal surface, making the possibility of corrosion or rust forming on the surface impossible.

Moreover, there are two-part epoxy primers that work more effectively by including zinc phosphate, which enhances the surface’s corrosion-inhibiting properties. Generally, epoxy is the ideal primer for bare metal surfaces.

2. Stacking Coatings

Since epoxy primers mechanically adhere to surfaces, they will immediately attach themselves to almost anything that has a good texture.

For that reason, epoxy primers are perfect for stacking or correcting areas to become uniformly flat.

Here, you will need to first apply a filler, feather the edges with sandpaper, and apply additional epoxy primer on the top of the surface.

3. Mixed Surfaces

Most coating and primers work best when the entire surface is uniform and made of the same material. Epoxy primers are well-known for their impressive adhesion properties, which help them firmly stick to paints, fillers, primers, and bare metal surfaces.

That said, you can comfortably coat the designated area that has been repaired with body fillers and then re-coated it into its original paint with epoxy primer.

It is often advisable to blend these areas perfectly before coating them with epoxy primers to help hide the imperfections well. Alternatively, you can opt to use a primer surfacer or filler over the epoxy to hide any minor imperfections.

4. To protect a long-term project.

Epoxy primers have provided reliable and effective solutions to people without spacy, climate-controlled shops to store their project vehicles.

This is because epoxy primers help lower the risk of corrosion and rust by preventing oxygen from reacting with the painted surface.

5. As a Final Sealer

Epoxy primers can also be used as final sealers before applying the last base coat. First, you paint a coat or two of epoxy primer on the entire surface and later add a base coat over the top to have a nice uniform surface.

Moreover, the primer has outstanding adhesive properties on most topcoats and will protect the original paint from peeling or flaking.

Is POR 15 Metal Prep Necessary?

POR 15 Metal prep is usually vital before the actual paint application because it helps the paint firmly stick to the painted surface.

Moreover, metal prep is really important, especially if you plan on painting shiny polished metal surfaces, like aluminum, which can be pretty challenging.

During meal prep, start by creating a perfect anchor pattern for the paint coating and gently scrape the paint remains from the surface.

POR 15 Metal Prep is necessary as it deposits a zinc phosphate coating that helps reinforce the firm chemical bonding between the surface and paint.

It is also advisable to avoid altogether metal prep jobs that result in the deposition of harmful residues on your perfect paint job finish.

Make sure that the POR 15 Metal Prep Formula is environmentally friendly and is not flammable, toxic, or corrosive when used with other coating products.

✔ Preps Metal for Paint – Gently etches bare metal and neutralizes rust while laying down a zinc phosphate layer for unbeatable coating adhesion.

✔ Boosts Coating Performance – Ensures strong chemical bonding with POR-15 Rust Preventive Coating or any paint applied afterward.

✔ Safe, Water-Based Formula – Non-toxic, non-corrosive, and easy to apply by brush, spray, roller, or dip.

✔ Ideal for DIY & Pro Projects – Use on auto parts, outdoor fixtures, fencing, and more to stop rust before it spreads.

Frequently Asked Questions

Below are some of the commonly asked questions about the use of the POR 15 Rust Preventive Formula:

Does POR 15 Need a Top Coat?

Yes, POR 15 needs an extra topcoat to last for a long period. This additional topcoat forms a firm barrier or covering on the surface that prevents the entry of moisture.

Thus, the painted surface remains protected against harsh weather conditions. Ultraviolet rays from the sun can also damage the POR 15 painted surface by breaking down the coating layer and eventually allowing moisture in.

A top coat helps alleviate this problem by providing optimal protection even if the surface is accidentally exposed to the UV rays of the sun.

Alternatively, you can decide to apply the topcoat directly to the initial painted metal substrates or surfaces.

When applying this topcoat, ensure to stir the POR 15 formula well before and during use. Avoid painting directly from the can, returning leftover paint into the can, or shaking the product before use.

Instead, you are advised to use a pouring spout to pour a portion of the POR 15 into a separate container and immediately seal the can to prevent it from drying.

How Long Does POR 15 Metal Prep Last?

POR 15 Metal Prep formula can last forever if not exposed to harsh weather elements that can damage it. Once damaged, large chunks of the formula fall off, and cranks are formed on the surface.

Metal Prep helps in enhancing better welding conductivity by completely removing rust from the metal surface.

Furthermore, the POR 15 Metal formula contains zinc phosphate that helps create a firm coat layer on the metal, preventing the entry of oxygen and moisture.

To ensure your POR 15 Metal Prep formula lasts for a long, regularly check for fissures on the surface.

Can You Spray POR 15 Out of a Paint Gun?

Yes, you can spray POR 15 Rust Preventive Formula out of a paint gun, but it is advisable to ensure that you thoroughly clean it with a lacquer thinner after use.

Spraying POR 15 out of a paint gun is also much faster when compared to using a paintbrush, especially over large surfaces.

Moreover, spraying this formula with a paint gun reduces the risk of paint getting into contact with your hands once you are done painting.

Since the paint may clog the paint gun and damage it, consider using a cheap one for spraying the POR 15 formula.

How Long Before You Can add a second Coat of POR 15?

It is often recommended that you should allow the first coat to dry within a 20 to 30-minute period to allow for a perfect and firm paint job.

Applying the second POR 15 coat can take between 2-72 hours, depending on the surrounding humidity levels and ambient temperatures.

The final POR 15 topcoat can be applied within 3-4 days, depending on its temperature and level of hardness.

Can You Put POR 15 Directly Over Rust?

You can apply POR 15 over surfaces with rust, but make sure the rust is not loose and edge the first coat to allow the POR 15 formula to stick firmly.

The formula also does not adhere well to shiny and smooth surfaces; thus, you are advised to make the necessary preparation to guarantee a perfect paint job finish.

Before application, make sure to clean the surface with POR-15 Cleaner Degreaser thoroughly, rinse with clean water, and allow to dry.

✔ Cleans Without Residue – Breaks down grease, oil, grime, and soap films on metal, vinyl, canvas, auto parts, and more—without leaving any film behind.

✔ Water-Based & Non-Flammable – Safer to use than harsh solvents and highly effective even when diluted up to 10:1 with water.

✔ Ideal for Prep Work – Perfect for prepping surfaces before paint or rust protection—pairs best with POR-15 Metal Prep for maximum coating adhesion.

✔ Multi-Surface Use – Great for degreasing engines, tires, rims, tools, undercarriages, and industrial equipment.

The POR 15 Rust Preventive Formula also does not work best with heavy, loose rust. The most effective way to deal with this is by sandblasting or grinding to remove this heavy rust.

By following these precautions, you are guaranteed a non-porous finish that is peel and moisture-resistant.

Was This Article Helpful?